Products

Processes

- Wastewater treatment

- Emulsion breaking

- Sludge dewatering

- Solid-liquid separation

- Heavy metal precipitation

- Oil sludge dewatering

- COD reduction

- AOX – treatment

- Soil washing

- Wash water treatment

- Decolourization

- Processing of recovered paper

- Trash catching

- Defoaming

- Retention

- Sedimentation acceleration

- Product overview

Branches

Wastewater treatment

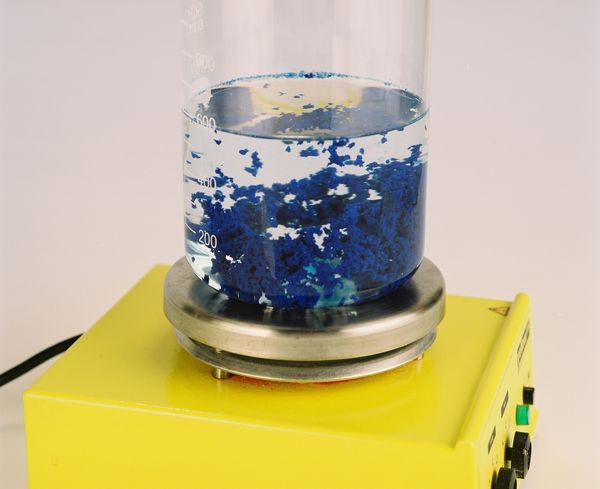

The use of polymer flocculants represents the state of the art in municipal as well as industrial wastewater plants and in biological or chemical wastewater treatment.

Principles of chemical watewater treatment

Chemicals such as splitters, coagulants and adsorbents are often used in wastewater treatment. In the first step, micro flocks are produced by

means of coagulation with POLY SEPAR® CFL. In the second step, the micro flocs are enlarged according to the dewatering aggregate by using coagulants, which are mostly in ready to use solutions. As an alternative to this, adsorbents tailored to each application case can also be used during batch treatment.

Chemicals for the preconditioning of wastewaters

Many different products can be used to pretreat wastewater at the source, i.e. before it is discharged into public sewage systems:

• Coagulation aids: inorganic metal salts as well as organic polyamines and PolyDADMACs serve as primary flocculants

• Polyer flocculants: for conditioning prior to sludge thickening and dewatering

• Emulsion breaking: to remove emulsified oils and fats

• Adsorbents: to bind small amounts of residual oils or other light contaminants, for example dyestuffs

• Charcoal and bentonite: for COD-reduction

• Defoamers: prevention and removal of floating sludge

• Deaerators: degassing of pulp

• Heavy metal precipitants: especially for the elimination of nickel and copper

• Crystallization inhibitors: for the prevention and removal of pipeline deposits (MAP or calcium compounds)

Reduction of sulphates and conductivity

Our newly developed product POLY SEPAR® CFX 2022 can effectively reduce the sulphate content and at the same time the conductivity in the wastwaters.

Contact

We would be pleased to offer you individual product advice to suit your specific requirements. Please use our contact form or call us at: +49 (0)4102-666-30.

We will be glad to provide consulting services on the required systems technology. Here, you can access our field service.

Contact

SEPAR CHEMIE Team

Please contact us should you have any questions.

Contact form

You could reach us also by telephone or by mail.

+49 (0)4102-666-30

info[at]separ-chemie.de

This year we have again supported „Doctors without Borders“ and UNICEF with a donation.

Opening Hours

Administration

Monday – Thursday: 8 a.m. – 5 p.m.

Friday: 8 a.m. – 3 p.m

Warehouse

Monday – Thursday: 8:30 a.m. – 4 p.m.

Friday: 8:30 a.m. – 2 p.m.

Our Partner Company in Sweden and Scandinavia:

Separ Chemie GmbH | Erika-Keck-Strasse 4 | DE – 22926 Ahrensburg | Phone:+49 (0)4102-666-30 | Email: info[at]separ-chemie.de