Products

Processes

- Wastewater treatment

- Emulsion breaking

- Sludge dewatering

- Solid-liquid separation

- Heavy metal precipitation

- Oil sludge dewatering

- COD reduction

- AOX – treatment

- Soil washing

- Wash water treatment

- Decolourization

- Processing of recovered paper

- Trash catching

- Defoaming

- Retention

- Sedimentation acceleration

- Productoverview

Branches

Emulsion breaking

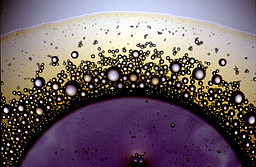

Emulsions are liquids distributed homogeneously in a mixture.

Application areas of emulsions

Oil-in-water emulsions, so-called cooling lubricants, are the emulsions most frequently used in industrial applications. To make these cooling lubricants (emulsions), an oil is emulsified homogeneously in an aqueous phase (approx. 5% oil) using emulsifying agents. Emulsions become contaminated after a certain amount of time and must be removed.

Organic emulsion splitting with SEPAR CHEMIE products

The process of separating the oil and water phase is called emulsion splitting, demulsication or coagulation. An oil phase floats to the surface, the water phase is transferred to futher wastewater treatment.

SEPAR CHEMIE uses organic emulsion breakers, which are more economical than standard acid cleavage for emulsion splitting. By using our mixed breakers from the POLY SEPAR® CFL-range, whose metal component removes surfactants etc., clear water is achieved.

Priciples of conventional acid cleavage

In conventional acid cleavage, the emulsion is heated to about 90°C and a strong acid is added to it. Under these conditions, the oil separates from the water phase and floats to the surface. This process requires a large amount of energy and can no longer be considered state-of-the-art, not least due to the high level of salinization of the water phase.

Contact

We would be pleased to offer you individual product advice to suit your specific requirements. Please use our contact form or call us at: +49 (0)4102-666-30.

We will be glad to provide consulting services on the required systems technology. Here, you can access our field service.

Contact

SEPAR CHEMIE Team

Please contact us should you have any questions.

Contact form

You could reach us also by telephone or by mail.

+49 (0)4102-666-30

info[at]separ-chemie.de

This year we have again supported „Doctors without Borders“ and UNICEF with a donation.

Opening Hours

Administration

Monday – Thursday: 8 a.m. – 5 p.m.

Friday: 8 a.m. – 3 p.m

Warehouse

Monday – Thursday: 8:30 a.m. – 4 p.m.

Friday: 8:30 a.m. – 2 p.m.

Our Partner Company in Sweden and Scandinavia:

Separ Chemie GmbH | Erika-Keck-Strasse 4 | DE – 22926 Ahrensburg | Phone:+49 (0)4102-666-30 | Email: info[at]separ-chemie.de